HANDLING EXPLAINED

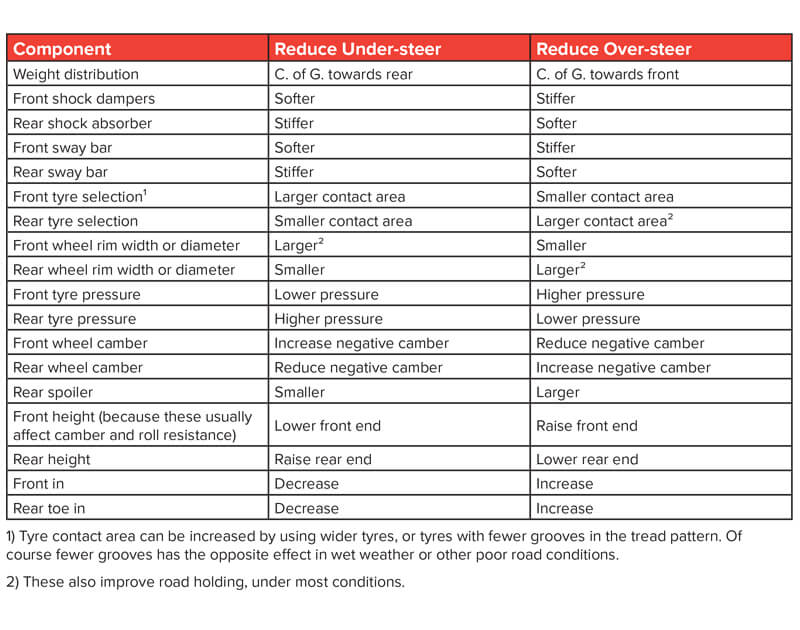

How does the spring rate affect the steering? Can the shock absorber rate reduce the body roll? Why does increasing the rate of the rear sway bar induce more over steer?

These are just a few of the questions we will examine in this TechStop on handling. But first, we should ask, “What is handling?” The technical definition of handling is generally accepted as, “the amount and percentage of traction each wheel and tyre has verses the feel to the driver of the car”.

Even this technical definition allows room for different opinions on how well a car handles because of differing characteristics of the car. A car must supply feel to the driver, and the most important element of handling is how well the tyres perform, remembering that in real terms the “foot print’ of the tyre is not that big and it relies on how well the car is “set-up”.

The ability of the tyres to maintain their grip is greatly influenced on the type, size and compound. If the car is fitted with the appropriate tyre for the intended use, fitted to the corresponding rims and the correct tyre pressure has been applied , then the car has good start to achieving the desired result. Handling is all encompassing, Acceleration, Braking and Cornering. For a car to achieve its true potential, all three of requirements must have the ability to come together. However the tyres will only work to their maximum effect if the steering and suspension allow them to. This is where we start to discuss the importance of dynamic geometry.

Though the wheel alignment geometry is adjusted while the vehicle is stationary, (static) it is important to note that it is for when the car is in motion (dynamic). Just about all the wheel angles alter when the car is in motion, this is where the suspension rate becomes active, you can have the best tyres money can buy, have the best wheel alignment performed on the car, but if the suspension is not right the car will not perform.

The dynamic changes of the geometry is effected by a number of factors, these including the general condition of the chassis and suspension, the static alignment angles, spring rates, shock absorber rates, sway bar rates and the balance of the car (corner weights and centre of gravity). This TechStop will examine how individual components impact on the overall package of a good handling car.

As we have touched on the importance of tyres and wheel alignment, the other major handling components of chassis tuning are: Springs, Shock absorbers , Anti sway bars (often called sway bars) and bushes.

Springs

Springs, whether they are Coil, Leaf, Torsion Bars or Air Bags, serve two basic functions. First and foremost they take care of holding up the sprung weight of the car, obviously if there were no springs the car would sit on the bump stops and that does NOT make for good handling. The second one is to provide resistance to the movement of the mass, vertically, pitch and roll. The velocity of this movement is controlled by the shock absorbers. The springs and shock absorbers are a matched set-up, make a choice on springs first, then select the shocks that are best suited to obtain maximum control.

The spring has many functions, like:

- Controlling dynamic Camber setting.

- The Ride Height, which effects the car’s Centre of Gravity and Roll Centres.

- The Roll Stiffness, which is the resistance for the body to roll when cornering.

To calculate what Spring Rate is required for the car the following data is required:

- Sprung weight of the car at each corner.

- Weight distribution, front to rear.

- Motion Ratio of the spring platform.

- Wheel Rate(Calculated spring rate at the wheel).

- Spring Angle, as mounted in the car.

- The compound of the tyres.

Shock Absorbers

Shock absorbers do not absorb shocks, they control the oscillations of the suspension movement, The stiffer the spring the stiffer the shock. They do this by controlling the compression and the rebounding of the suspension as the car travels over a given surface. Also they will have an effect on the energy created associated with suspension travelling laterally created by cornering and longitudinal, created by accelerating and braking.

Without damping, the magnitude of the suspension movement would never stop increasing. In terms of energy, damping absorbs most of the energy the car receives as it moves, unlike springs, that store the energy and then releases it. Imagine a car with no damping effect or the wrong valving in the shock absorber. The subsequent impacts from the undulations on the tyres would make the suspension uncontrollable, which is not a good thing. Dampers absorb all the excess energy and allow the tyres to stay in contact with the road surface as much as possible.

This also indicates that the damping rate should always be matched to the spring rate.

Note: the damping only alters the speed at which the roll and pitching motions occur, it does not alter their extent. So if you want the vehicle to roll less, adjust the Anti-Roll bars or change the spring rate, leave the shocks last.

How to select the shock absorber

- Check the suspension travel, the shock must have the correct opened and closed length.

- Take into account the “Motion Ratio” when selecting the valve code.

- The angle that the shock absorber is mounted will also affect the valve rate.

- The shock absorber valve code is to be matched to the spring rate.

Anti-Sway Bars

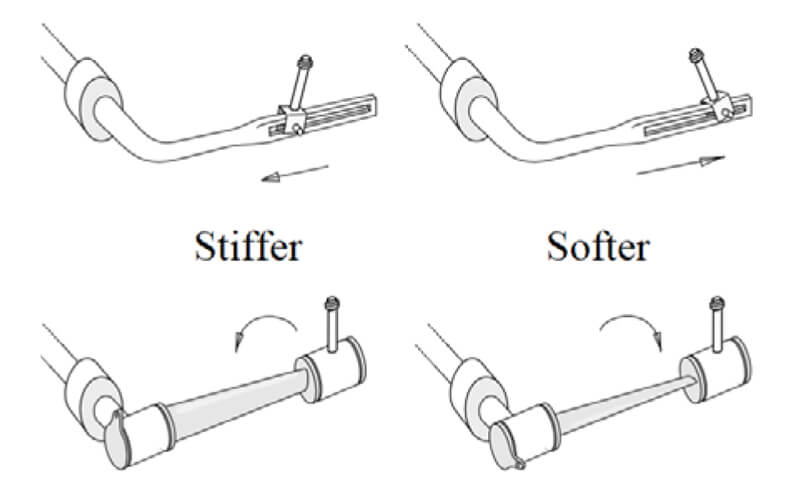

Anti-sway bars are like “sideways springs, they work laterally. If one side of the suspension is compressed, one end of the bar is lifted. The other end will also want to go up, and in turn pulling the other side of the suspension up also, basically creating more resistance to body roll. This effect is controlled by the torsional strength of the bar, smaller diameter less resistance, larger the bar, the greater the resistance. When both sides are moving equally, down when the car is braking or up when the car is accelerating, the bar has no effect on the suspension. Anti- Roll Bars only effect the lateral balance of the car, not the longitudinal balance.

- Anti-Roll Bars aren’t the only things that effect the car’s roll stiffness, they work in conjunction with the springs and shocks.

- Stiffer in the front and softer in the rear, promotes understeer.

- Softer in the front and stiffer in the rear promotes oversteer

- Anti –Sway Bars will restrict suspension travel, so be mindful of this when going off road with your 4 W.D.

Some anti-roll bars, particularly those intended for racing, are externally adjustable while the car is in the pit whereas some systems can be adjusted in real time by the driver from inside the car. This allows the stiffness to be altered, for example by increasing or reducing the length of the lever arms on some systems, or by rotating a flat lever arm from a stiff edge-on position to a more flexible flat-side-on position on other systems. This lets a mechanic tune the roll stiffness for different situations without replacing the entire bar.

Suspension Bushes

Suspension bushes are one of the most poorly understood and undervalued components of a car’s overall handling. It can be easy to discount the role that such an inconsequential looking piece of rubber can play in the proper operation of a car’s suspension system. This is a huge mistake. Although a suspension bush looks simple, it is quite a complex component that fulfills a variety of important roles and if they become worn or damaged you will notice a variety of adverse effects.

The following are some of the classic symptoms:

- Excessive road noise.

- Poor steering response.

- Poor handling (Over or Understeer characteristics).

- Inaccurate wheel alignment.

- Not obtaining the full the effects of the tyre foot print.

The use of different types of materials for the bushes, do have their advantage:

- A high capacity to bear tension.

- Assist in more precise wheel alignments.

- The car becoming more reactive.

- Increase road holding.

When installing any suspension bushes, only tighten the mounting bolts finger tight. Do not proceed until the car’s weight is resting on the wheels and the car is at natural ride height. Then fully tighten the bolts to the recommended torque. This procedure will prevent premature wear of the bushes caused by increased torsional stress placed on them. The ride height may also be affected if this process is not followed.

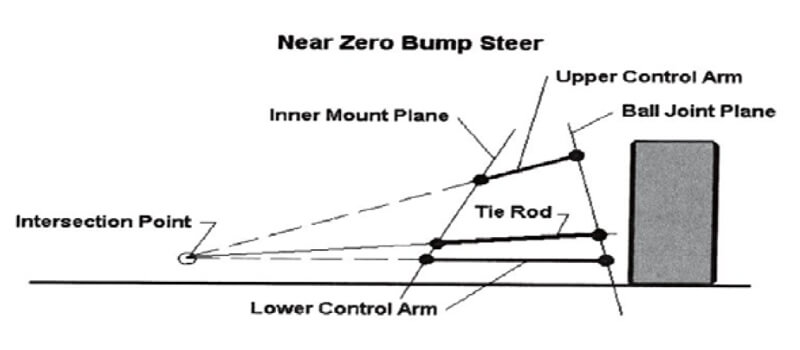

Bump Steer

Bump steer is the toe-in or toe-out of the front wheels as the suspension goes from normal ride height through full bump (suspension system moves up) to full droop (suspension system moves down). Measurement is usually limited to 75mm up and 75mm down from ride height. It is specified either by a graph or measurements at 25mm, 50mm and 75mm.

So, what does bump-steer do to a car’s handling? There are a number of possibilities, depending on the severity of the problem in, including:

- Direction change under braking.

- Shake in the steering system (particularly at the steering wheel).

- Sudden loss of grip during any part of the cornering process (entry, middle, or exit).

- The car pulls to one side at certain points on the track (can be on straights too).

All of the above are directly related to suspension movement at a time when the driver did not input any steering angle change.

Although bump-steer is predominantly a front end geometry problem, certain suspension systems can produce similar problems on the rear of a car, for instance fully independent suspension systems.

In general, most high technology cars, have very little bump-steer. The accuracy of the design and build process on these cars ensures the geometrical accuracy.

Measuring bump-steer is simply a case of measuring the deviation a wheel takes when the suspension is compressed. Very accurate instruments such as a modern four wheel alignment machine can measure deviation as little as one mm. Changing the vertical position of the steering rack or rod-end pivots will change the bump-steer readings.

Causes of Bump Steer:

- Steering Rack not level.

- Drag link not level.

- Different length Ackerman arms.

- Different height or angle of the Ackerman arms.

- Tie rod and L.C.A. angles do not intersect.

- Height of steering gear.

- Bent or misaligned steering components.

Wheel Alignment

The final operation of any modification, alteration or set up is the wheel alignment, why?

- Directional stability.

- Obtain maximum affect from the tyres.

- Stable braking.

A poor or no wheel alignment will result in a vehicle that will be lacking in the appropriate responses. The tyre foot print is quite small in the scheme of things, it is all very well in having an engine that is developing good reliable horse power, but if the car can’t put it on to the ground, then you are wasting your time.

Not all cars and drivers like the same settings, as there are too many variables.

- The balance of the car.

- The weight of the driver.

- The driving style.

- The tyre pressures.

- The type/compound of tyres

When conducting the wheel alignment, it is very important to have the car at it’s usual operating weight. All fluids, including fuel, oils, washer bottle, driver drink bottle etc., must be at their desired level. Tyre pressures correct, drivers weight, including clothing and helmet, is to be in the car.

If you are using your car for competition, make sure you set the geometry up for the car to suit the circuit. The toe setting will vary enormously from circuit to circuit. Is it short tight and twisty or open and fast. These are the considerations to be taken into account when setting up the vehicle.

A tyre temperature gauge is very handy as well. After a test session check the temperature across the foot print of the tyre, to see if there are any major variations and if there are alter the geometry to have a uniform temperature pattern across the tyre.

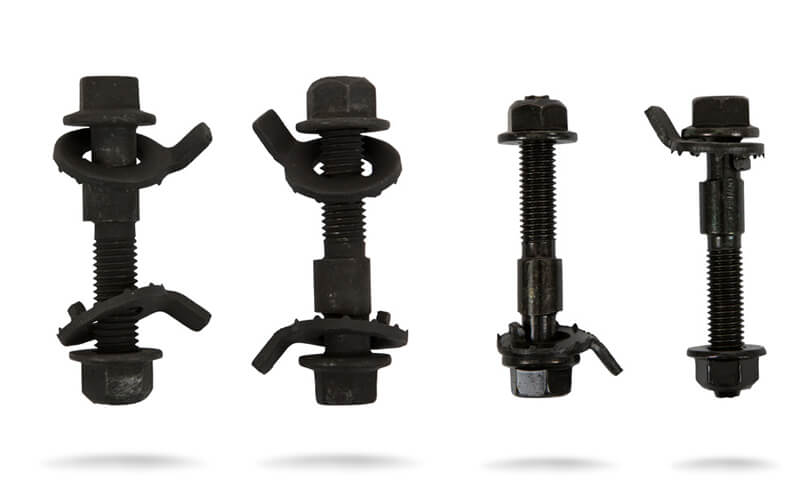

Pedders Wheel Alignment products

Pedders suspension have available an extensive range of aftermarket wheel alignment products. So now there is no need to put up with “close enough is good enough”

In the Pedders range, there are Eccentric Bushes, Eccentric Pivot Bearings, Camber Pins, Shim Replacement Kits and Adjustable front Radius Arm Bushes.

Handy Hints