First of all, we must understand that the carrying of extra weight will affect the whole dynamic characteristics of your car. These include; accelerating, braking, cornering, power to weight ratio and fuel economy.

Definition of Vehicle Dynamics:

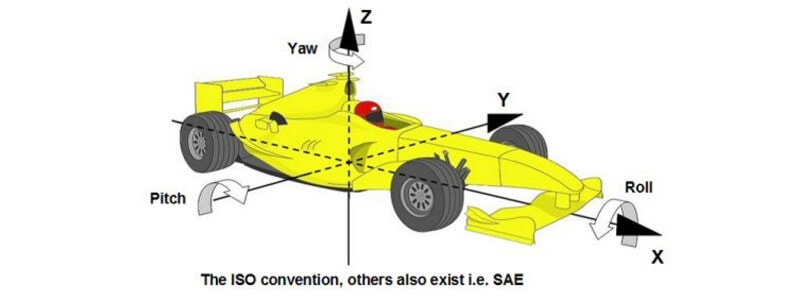

Vehicle performance and handling are affected by speed, weight, load distribution and road surface. Increase or decrease in weight, increase or decrease in speed, the pitch and roll will all effect the responsiveness of the car responding to various situations and this depends on whether you are and at what rate:

- Accelerating = Pitch “Y” rear down, front up

- Braking = Pitch “Y” front down, rear up

- Turning = Roll “X” outside down, inside up

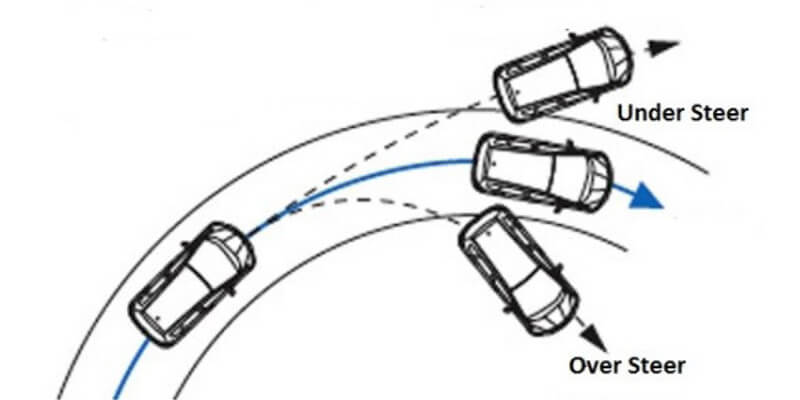

- The “Yaw” = “Z” under or over steer

All three axis are reliant on the effectiveness of the shock absorbers, springs, steering, brakes and wheel alignment. There is no escaping vehicle dynamic physics.

How much weight do you think will affect the car?

Accessories, such as Bull Bar with Winch, Driving Lights, Extra fuel tanks or a Roof Rack.

- What’s the seating capacity, how much weight is accumulated with the occupants?

- Is the car towing a 6×4 box trailer or a 30 foot Caravan, or what about a double horse float?

- If you are going on a road trip, what’s the weight being carried and how is it loaded within the car?

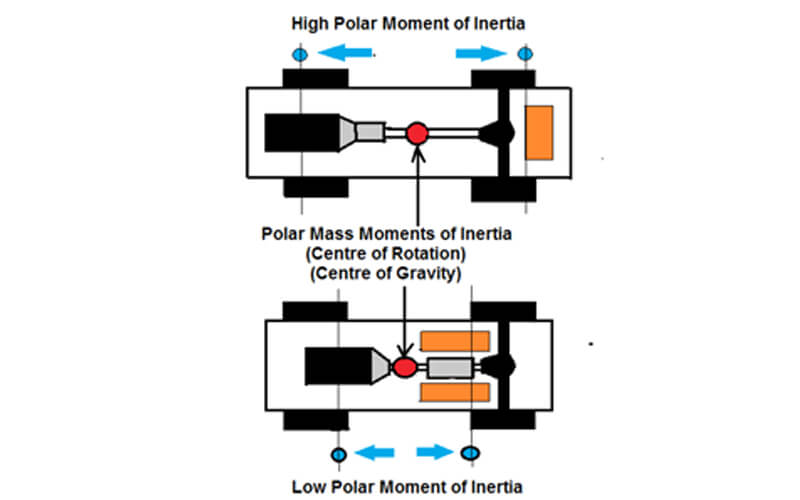

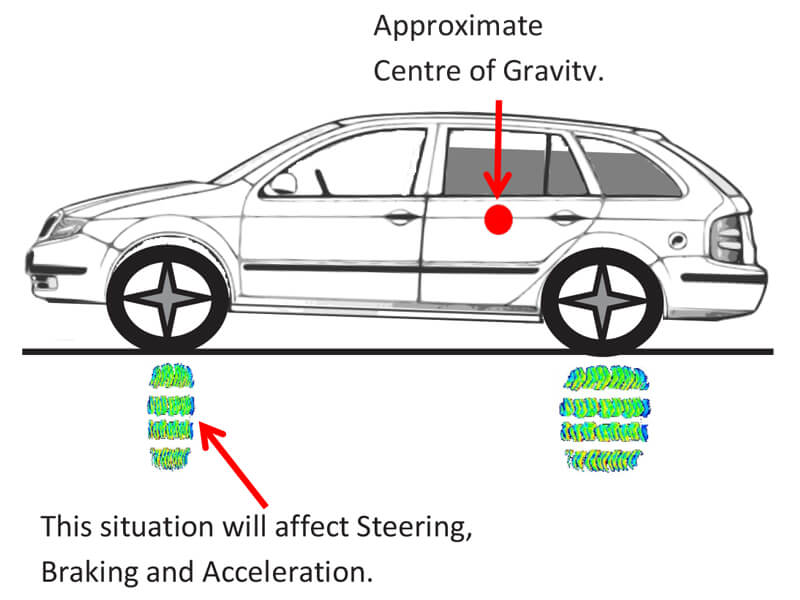

Every vehicle has a “Polar Moment of Inertia” which is the Centre of Rotation around the car’s Centre of Gravity. This “Moment“ will be effected every time weight is added also where it has been placed within the car.

The idea is to keep the majority of the car’s mass as close to the axis for maximum balance. When the mass of an object is distributed far from its axis of rotation, the object is said to have a high polar moment of inertia and Lateral forces will have a higher impact on the car’s ability to negotiate a bend in the road. If there is too much weight over the front of the car, it could “under steer”. When there is too much weight over the rear, then the car could “over steer”, especially on a loose or wet surface, the back could “step-out”. When the mass distribution is close to the axis of rotation, it has a low polar moment of inertia and the car will be more responsive to instructions given to it by the driver. Also this will give the car a greater ability to handle undulating and winding roads.

To experience a practical example, stack some bricks in a wheelbarrow over the wheel and try running around a corner. Now stack the bricks near the handles and repeat, If I was a betting man, you noticed that it was easier to control the wheel barrow when the bricks were closest to the wheel (i.e. C.of G.)

So how does this affect the family car?

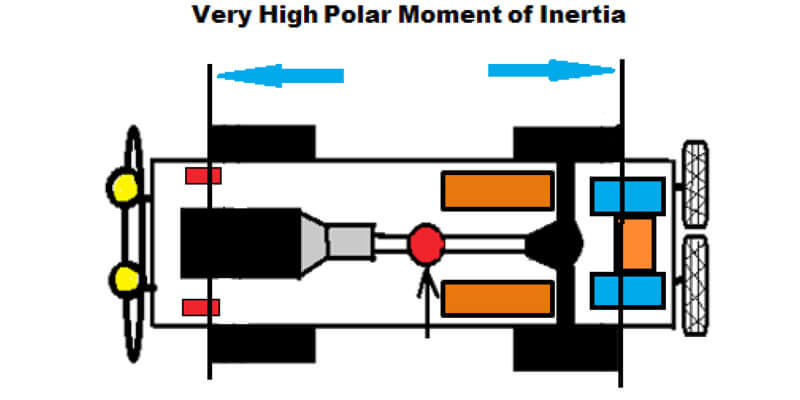

Well let’s have a look at what type of accessories that may be fitted to the car that will influence the Polar Moment of inertia. The placement of weight in, on and around the vehicle will dramatically effect the position of the “centre of gravity” of the vehicle.

Well let’s have a look at what type of accessories that may be fitted to the car that will influence the Polar Moment of inertia. The placement of weight in, on and around the vehicle will dramatically effect the position of the “centre of gravity” of the vehicle.

- A bull bar and winch is fitted to the front, which adds front axle weight.

- The two spare wheels are bolted to the rear.

- Extra fuel tanks, extra batteries, a set of rear draws etc

Are you starting to understand that weight will affect the ride, handling and stability of the vehicle? If nothing is done to upgrade the suspension in proportion to the load being carried, your big road trip, which you have been planning for 12 months, could end up very ugly.

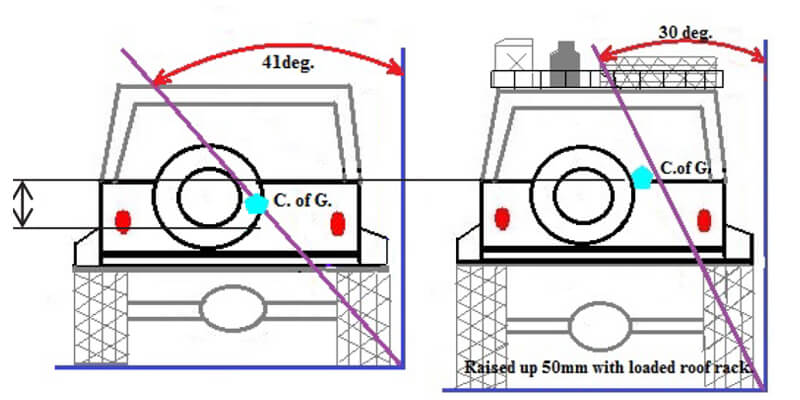

The area we are focusing on now, is the effect of the placing a load on a roof rack. The higher the load, the higher the vehicle’s Centre of Gravity.

As the C.of G. goes up so does the ability of the car to negotiate bends in the road with the same agility of a car that has not had its C.of G. raised. For example, the higher the C of G, the harder it is to control the dynamic impact of the weight.

To offer you a practical demonstration, how easy is it to manipulate and control a hammer when the mass of the head is low, against the hammer which has a larger mass. Try it, and feel the difference. Now think about it, in a little bit bigger scale and relate this to the loading of the car.

All the sprung and unsprung weight of a car, has the potential to become Kinetic Energy, (energy in motion), so the lighter the car the more responsive its going to be to the driver’s instructions.

The more weight that is added and more importantly, the position it is placed, has the potential to affect the steering and handling of the car. Understeer – the front of the vehicle won’t respond to the desired steering inputs and inertia pushes the front of the vehicle where you don’t want it to go.

Oversteer – the rear of the vehicle over reacts to your steering input as inertia converts potential energy of the weight into kinetic energy and the back out of the vehicle steps out and creates “over steer”. Increased weight mass also greatly extends braking distances: Now pile 500kg into the vehicle and look at the 5 key areas of critical automotive importance:

- Front and rear ride height (front – up and rear – down)

- Springs

- Shock absorbers

- Suspension geometry

- Braking distance

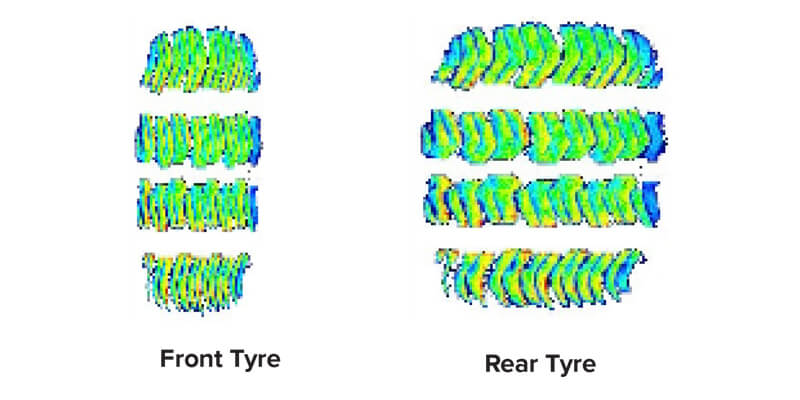

For example, if you use a twice folded piece of A4 paper, this is indicative of how small the average tyre contact patch is with the road. How many times have we all witnessed a vehicle travelling down the road, excessively overloaded? Forget the A4 paper folded in half…The reality is, the front tyre contact with the road, will look much more like this.

Now your front tyre to road contact patch looks something like a bicycle tyre! Resolving this problem involves much more than simply throwing a set of springs in the rear. This is why Pedders offer the “whole of vehicle” approach when formulating a remedy in fixing the problem and not to have the “Band-Aid” approach.

One size does not fit all when searching for load carrying solutions and the same is true for managing simple everyday light load driving too. Remember, the five key areas of critical automotive importance!

When 1 second, 1 metre, or 1 moment really counts, you’ll be glad you trusted the experts at Pedders to help craft the right customized solution for your individual needs.

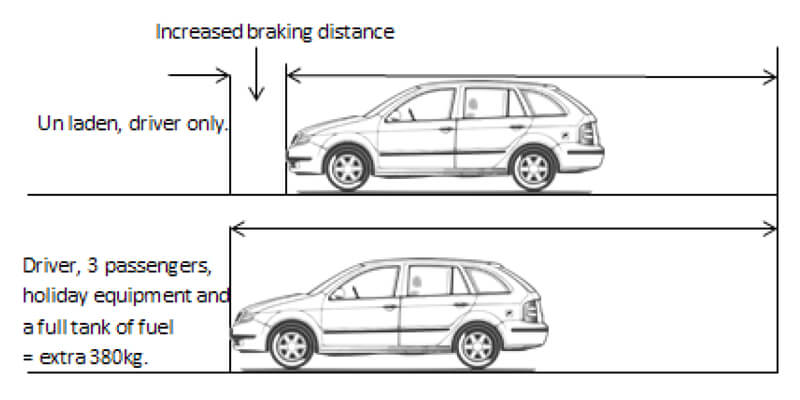

To reinforce a simple understanding of weight in dynamics terms, consider the impact of weight and these numbers of a vehicle travelling at 60kph.

- Typical SUV, empty, with a single driver and some fuel = 1800 kg.

- Add a 380 kg load.

This is what happens

- Stopping distance empty = 45 (in metres)

- Stopping distance loaded = 47 (in metres)

- Direction change empty = 0.65 (g moment)

- Direction change loaded = 0.95 (g moment)

Disclaimer: The figures quoted are very subjective, as there are many variables involved when braking occurs in real life situations, such as:

- Condition and type of brakes

- Road condition, Wet or Dry, gravel or bitumen

- Tyre type, size and condition

- Driver’s reaction time

- Weight of vehicle

But they are an indication of “cause and Effect”

Techstop Hints

- If the car is going on a road trip towing, or heavily laden, have a Tech Check and Report done. Including the brake fluid condition.

- Do a calculation of the weight that is to be placed into the car. This is to include the weight of the occupants.

- Be aware of the O.E.M.’s maximum Gross Vehicle Mass. (G.V.M.) do not exceed this figure.

- Before loading the car, plan where the items are going to be placed.

- Always place the heaviest items as low as possible.

- Distribute the load as evenly as possible within the car, front to back and side to side.

- If a roof rack is fitted, only place light items up high, clothes soft bags etc.

- Make yourself aware of the maximum towing mass, for un-braked and braked trailers/caravans.

- Check tyre pressures and don’t forget the spares.

- Have a wheel alignment performed on the vehicle in it’s “Ready To Go” state